Hard Hat Compressed Air Maintenance Workshop

This two-day, 4-hour workshop, designed for facility engineers and facility maintenance technicians, will cover how to ensure reliable compressed air supply and deliver huge energy savings able to allow plants to hit carbon emission reduction targets.

Attendees will learn maintenance inspection practices in the air compressor room and how to launch energy-saving air-blow and compressed air leak detection programs targeting pneumatic-powered machinery in production areas (bag-makers, pouch-fillers, vacuum sealers, heat sealers, material handling, drying, conveying, powder-coating, CNC routers, bottling, filling, cap sorters….) and packaging areas (case packers, automatic cartoners, palletizers, shrink wrappers, carton/case erectors…).

This interactive, hands-on workshop features fully operational table-top compressed air labs with pneumatic circuits where participants see the impacts caused by pressure loss and flow variations, while identifying the locations, causes, repairs, and quantification of compressed air leaks. Attendees will receive a project list to take back to the facility to find new levels of uptime and carbon reduction projects requiring no down-time and zero-to-little capital cost.

Attendees will earn 4 PDH credits.

Join these national experts in facility maintenance, pneumatics, compressed air leak detection and system auditing!

Jon Jensen, Energy Efficiency Group Manager, SMC Corporation of America

John Bilsky, Facilities Specialist for Compressed Air - N2 - Purified Water, Gentex Corporation

Josh Wamser, Auditor and Trainer, Industrial Compressor Solutions

Chase Sasser, Regional Operations Manager, UE Systems

Company A Sites

|

Location |

Total Losses CFM |

Total Savings |

|

Location 4 |

728 |

$259,896 |

|

Location 2 |

2,177 |

$777,189 |

|

Location 1 |

3,277 |

$625,907 |

|

Location 3 |

516 |

$119,196 |

|

Location 5 |

989 |

$274,942 |

|

Location 6 |

2,128 |

$138,320 |

Training maintenance in each plant to conduct compressed air leak surveys can deliver significant energy savings. Source: PCE Compressed Air Leak Surveys for the Petrochemical Industry, Compressed Air Best Practices Magazine, May 2017 Issue.

Tuesday, October 29th – 8:00 – 10:00 AM

Session #1: Understand Your Compressed Air System and its Energy Cost/Carbon Impact

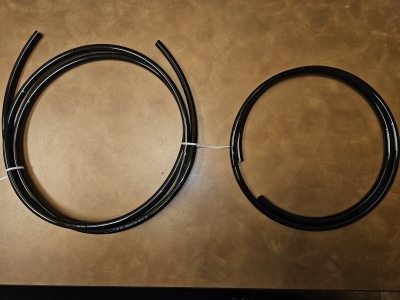

Lab 1: Learn how undersized and poorly connected pneumatic circuits (tubing, couplers, quick disconnects) create large pressure losses and leaks in the last 30 feet between the piping ring and production equipment- AND reduce production output

- Make a block diagram and document detailing all the equipment in the compressed air system

- Map the piping system including pipe diameters and materials

- List Key Performance Indicators (KPIs)

- Know the compressed air quality specification

- Estimate the energy cost and carbon emissions impact

- Identify what measurement instruments exist for energy use, flow, pressure and pressure drop

- Learn where to install pressure gauges in the air compressor room. What is the pressure loss in the air compressor room?

- Understand IF there will be energy cost savings IF compressed air flow or pressure is reduced

- Create a rule of thumb for the average energy cost of compressed air leaks and pressure drop

Session #2: Understand the Compressed Air Requirements of Production and Packaging Areas

Lab 2: How Compressed Air is Commonly Misused in Air Blow Applications. Low-cost solutions for big energy savings

- Document where/why compressed air is used. Establish zones. What is being produced, hours of operation, lowest compressed air pressure requirements?

- List how is compressed air being used (pneumatics, air-blow (drying/sorting/blowing), a process, instrument air)

- What is the cost of downtime in the production and packaging areas

- Does compressed air caused downtime occur? How often? Is it related to air pressure or air quality?

- Is there an air quality specification for each zone?

- Learn how different compressed air users/processes impact each other. How to recognize problems

- Where to install flow meters and gauges in production/packaging areas

- Daily process monitoring tips. Where/what to monitor and predict/catch failures

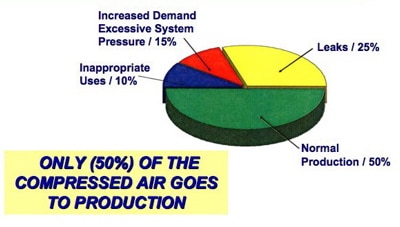

- Focus on Air-blow misapplications using excessive flow or pressure. Energy-saving solutions

Most leaks occur in the connection points and tubing to production and packaging equipment. Reference: DENSO Compressed Air Leak Detection Program Drives CO2 Reduction Results, Compressed Air Best Practices Magazine, January/February 2024 Issue.

Wednesday October 30th – 8:00 – 10:00 AM

Session #3: Taking Action: Redundancy Planning, Maintenance Logging, Work Orders, and Daily/Weekly Manual or Automatic Inspections for System Faults

Lab 3: Simulate Troubleshooting Compressed Air System Faults Able to Cause Downtime. Simulate Pressure, Flow and Air Quality Problems – how to detect and how to fix

- Air Compressor Room

- Make maintenance & service easier: removing clutter, cleaning and labeling

- Cleaning/Checking Work Orders: cooling air flow in air compressor room, air compressor cabinets, dryers, filters

- Compressed Air Condensate drain map and inspections

- Create a redundancy plan if an air compressor or dryer goes down

- The Last 30 feet of Connections to Production/Packaging Equipment

- Mapping and monitoring pressure gauges for pressure loss

- Work Orders for pneumatic circuit air leaks and pressure loss; split feed hoses, fittings, couplings, quick disconnects

- Focus on FRLs: Clogged filters, regulator replacements, lubricators insertion oil into process/inserting oil), pneumatic circuits

- Start with Manual and Evolve to Automatic (remote monitoring) Inspections and Alarms

Session #4: Taking Action: Set up a Compressed Air Leak Management Program

Lab 4: Hands-on instruction on the use of compressed air leak detection equipment finding live air leaks on pneumatic circuits

- Quick review of leak detection technologies available; discuss use of audio or visual style equipment

- Leak Detection Equipment optimum settings: sensitivity, frequencies, and modules

- Review a success template for a successful compressed air leak detection PM (preventative maintenance program)

- Logistics of a compressed air leak survey: setting zones, walk the line, identifying competing sounds and mitigating them

- How to find, tag, and measure compressed air leaks. Gross to fine method scanning. What type of tag (two-part tag or surveyors tape), dB measurement data gathering

- Reporting: What method is easiest for you – handwritten or using an App? What does a report look like?

- How to tie Leak Survey Reports to maintenance work orders

- Quantifying accurate energy savings and carbon emission reductions

- Repairing: Methods, materials and work orders

The workshop teaches how to eliminate most compressed air Inappropriate Uses and Leaks.